EK-7 advantage

1、Real time temperature curve measurement

2、Large data storage capacity

3、Sophisticated hardware

4、Durable hardware

5、Automatic insurance operations

6、EK-7 Thermometer Data Sheet

7、EK-7 Thermometer A4 Data Sheet

Real time temperature curve measurement

Real-time data transmission is realized through industrial Bluetooth technology and is currently the best reliable transmission technology. To ensure the integrity of the data 100 %, the curve data will be retransmitted once after the measurement process is over to ensure that the packet is not lost during transmission.

Data storage capacity

The EK-7's built-in flash memory can accommodate 1,000 welding temperature curve measurements without downloading curve data after each measurement.

Data storage capacity

1、EK7 is a new generation of temperature curve tester. Its exquisite and sturdy design is suitable for most thermal process applications.

2、All aluminum alloy shell, so that the use of the thermometer can meet the most harsh production environment.

3、The high-performance configuration of the 32-bit chip CPU ensures that there is no lag in the running process.

4、Equipped with regeable lithium batteries, it can be used for several hours after each full ge.

Excellent software forecasting function

KIC Navigator automatic predictor/optimization technology has won the industry award, which can immediately improve the curve parameter setting ability. There is no need for repeated trial and error attempts to set up the stove before mass production begins. This will greatly reduce crash time and translate into higher productivity.

Automatic insurance operations

All valid data will be copied and stored as a backup file in the EK-7 flash memory. In any case, if the thermometer is suddenly turned off during use, do not worry. The backup file is already in the EK-7's built-in flash memory and can be extracted at any time.

If the operator forgets to turn off the power after the operation is completed, the EK-7 will automatically shut down after 20 minutes to save electricity.

Upgraded to Automatic Temperature Curve Test System

The EK-7 can be upgraded to the KIC automatic temperature curve test system, which will give you more advantages in the market competition and raise your production technology to a new level-providing a temperature curve for each PCB, bar code tracking, SPC ts, data transmission to MES systems, etc..

* Specifications are subject to change without prior notice.

Remarks:The cooling of the thermometer to room temperature is still mandatory to prevent the instrument from aging in advance.

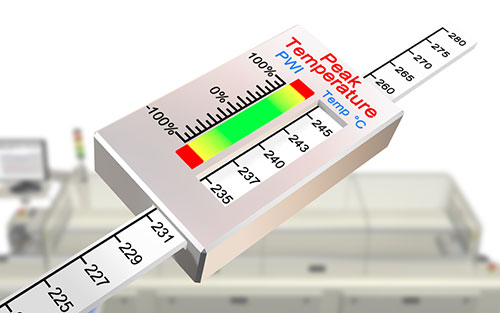

Process Window Index

Use a simplified value to indicate the degree of conformity of the temperature curve

PWI is a simple value that objectively reflects whether the temperature curve measured from a mathematical point of view conforms to the process window. This method compares and ranks the different temperature curves to determine their conformity with the process window, and thus helps the process optimization. The lower the PWI, the higher the process efficiency, the more stable the process! (See PWI Data Table for details)